material:304

internal surface treatment:electrolytic polishing

the finsih of external surface treatment:Ra≤0.2um

design pressure:0.6Mpa

design temperature:60°C

working pressure:0.09Mpa

capacity:112 L

air tightness test:the test medium is clean compressed air, which is slowly pressurized to 0.6Mpa, maintained for 10 minutes, and then reduced to 0.09Mpa.

Leakage is unacceptable.

1. The barrel body is made of high-quality SUS316L and SUS304L stainless steel plates (customer-approved), which are corrosion-resistant and acid-resistant.

2. Tungsten inert gas arc welding machine (TIG) is used, single-sided welding and double-sided forming are used, the weld is beautiful and smooth, there is no weld nodule, welding slag, the tightness is safe and reliable, and it can withstand a pressure of 0.6MPA, which is more pressure-resistant and stronger.

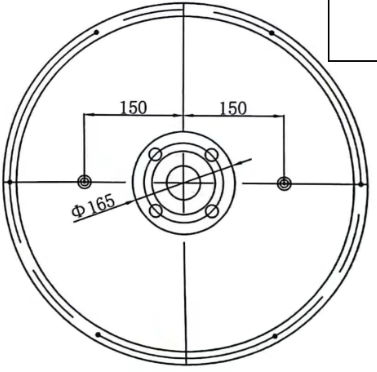

3. Barrel mouth design: standard flange connection method is adopted, tetrafluoroethylene is sealed, leak-proof and corrosion-resistant.

4. The upper and lower barrel bodies adopt integral stamping heads, upper and lower skirt structures, and high skirt protection cover barrel body valves are installed to avoid leakage. The upper skirt has a handle, which is safe and convenient to use.

5. The outer surface of the barrel body adopts mechanical mirror polishing, and the inside of the barrel adopts electrochemical pickling passivation treatment for long-term storage and safe use of the product.

6. Other barrel types can be designed and manufactured according to customer requirements.

Contact: Christine Green

Phone: 86-155 8987 8753

E-mail: info@theoryemtech.com

Whatsapp:86-137 8063 1263

Add: Offcie Building Phase 1.2 of Vanke City,No.99 Changzhou Road Dongge Street ,Pingdu City, Qingdao,China